- + 44 (0) 1484 515 112

- sales@hgkippax.co.uk

- West Yorkshire England, HD5 8HF

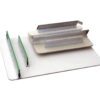

FLOCKING MACHINE

FLOCKING MACHINE

Add a unique look to your custom garments with Anatol’s flocking system.

Flocker unit is available in two models with flocking areas of 15” x 17” (38cm x 43cm) or 20” x 28” (51cm x 71cm).

Description

For those screen printing shops looking to take on flocking, Anatol has you covered. The Anatol Flocking Machine easily installs into a designated print station on your screen printing equipment, allowing the operator to combine both screen printing and flocking on the same t-shirt printing press.

The Anatol Flocking system gives shops the ability to add flocking to t-shirts and other textiles. The adhesive applicator ensures adhesive is applied only to the area to be flocked. The head-mounted vacuum helps to keep the work area clean and minimizes lint in the shop. Additional modules can be added to handle multi-color flocking designs. The flocker system is mounted on a stand with caster to easily move it wherever you need it.

Standard Features

Operation

- Adhesive applies only to the specific area to be coated with flocking

- Head-mounted Vacuum Cleaning Units necessary for cleaning after the flocking process

- Can combine multiple modules on a press for multi-color flocking

Construction

- Steel mesh screen

- Sealed flock container prevents contamination for a clean flocking process

- Fully integrates into most Anatol automatic screen printing presses

- Electrostatic generator included

- Accommodates frames from 26″ x 31″ (66 cm x 79 cm) to 31″ x 43″ (79 cm x 109 cm)

Specifications

| Flocking Area | Electrical Requirements | ||||

|---|---|---|---|---|---|

| 15″ x 17″ 38cm x 43cm |

1 Phase, 115 VAC, 2 AMPS, 60 Hz, 1.38 kW 1 Phase, 230 VAC, 2 AMPS, 50 Hz, 1.38 kW |

||||

| 20″ x 28″ 51cm x 71cm |

1 Phase, 115 VAC, 2 AMPS, 60 Hz, 1.38 kW 1 Phase, 230 VAC, 2 AMPS, 50 Hz, 1.38 kW |